Paper Grain? It Matters

Printers and paper specifiers spend a lot of time looking at papers. Their textures, colors, and weights are very important in any print project..

But what about the paper grain?

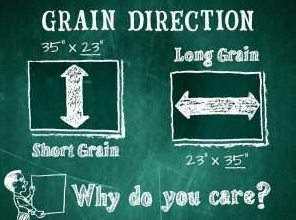

Paper grain is the direction of fibers in a sheet or web of paper, generated during paper formation. As paper moves forward along the forming wire on a papermaking machine, the fibers align themselves in a

direction parallel to the direction of wire travel through the machine. When paper is cut into sheets, it will be either long-grain if the fibers are aligned parallel to the sheet’s longer dimension or short-grain if the fibers are aligned parallel to the sheet’s shorter dimension. Paper will tear and fold more easily with the grain and with greater difficulty against the grain.

A paper mill may indicate paper grain on carton and ream labels, product brochures, swatch books and price lists in several ways: You may see the words Grain Long or Grain Short. Or the dimension parallel to the grain may be underscored.

Paper will also fold more easily when you fold with the grain. Folding against the grain not only makes folding evenly more difficult, it will potentially lead to cracking of the fibers on the fold. The heavier the weight of the paper the greater the degree of cracking. When folding projects with lots of coverage or heavy weight papers, scoring is recommended on all weights when you fold against the grain. When folding in the grain direction, most coated mills recommend scoring any text weight 100# and up and all cover weights.